Jiangxi Hongtu IoT Technology Co., Ltd. is located in Nancheng County, Fuzhou City, Jiangxi Province. With a beautiful park environment, a people-oriented management policy, and a production philosophy that focuses on product quality.

Since its establishment, our company has always adhered to the manufacturing direction of "full process production, full process control, and all-round service", achieving full process automation from raw materials to finished products, and producing and shipping with high quality and efficiency.

At the same time, the company has also established its own brand, "Hongzhiyu". We serve our global customers based on the principles of "Hongtu", "intelligence as the foundation", and "reputation as the purpose".

SMT production workshop

SMT surface mount is an important part of electronic product manufacturing, so the company has introduced advanced surface mount production lines to grasp the product from the front-end surface mount process, ensuring that every solder joint, electronic component, and motherboard is "highly accurate and zero error"

Finished product assembly workshop

We have "professional assembly technicians, rich production assembly experience, automated assembly production lines, more than 15 years of production management talents, and a sound quality management system". Ensure strict quality control at every stage of assembly, testing, packaging, etc., to guarantee product quality and production efficiency.

Experimental Testing Center

The company has sound testing equipment that can conduct various reliability tests, including drop, high and low temperature, EMC, safety regulations, environment, and more. To safeguard product quality.

Salt spray testing machine

The environmental test mainly uses the artificial simulation of salt spray environmental conditions created by salt spray testing equipment to assess the corrosion resistance of products or metal materials.

Simulated transportation vibration table

The purpose of simulating transportation vibration table is to conduct a series of controllable vibration simulations in experiments, test whether the product can withstand the test of transportation or vibration environmental factors during its life cycle, and determine the requirements and standards for product design and functionality.

High and low temperature testing chamber

The purpose of high and low temperature testing is to determine the adaptability of electronic products to the environment when stored or used under high and low temperature conditions. The adaptability under high and low temperature conditions refers to the ability of a product to remain intact, undamaged, and function normally when stored or used under constant high and low temperature conditions.

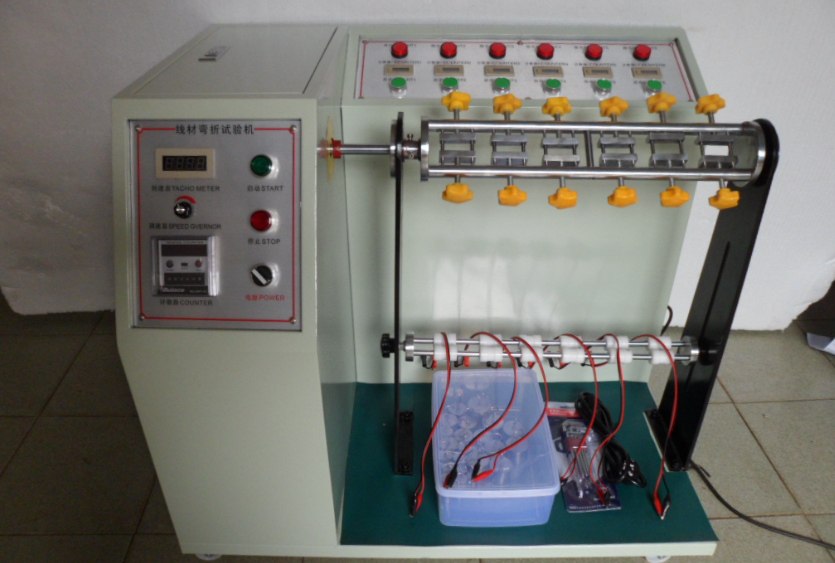

Wire bending testing machine

The purpose of the wire bending test machine is for manufacturers and quality inspection departments to conduct bending tests on power and DC wires. Used for testing the bending resistance and performance of wires, cables, and various products under certain conditions such as speed, angle, weight, and frequency.

Drop testing machine

The purpose of the drop testing machine is to test the damage caused by product packaging when it is dropped, and to evaluate the impact resistance of electronic components when they are moved.

Programmable Rain Test Chamber

The rain waterproof test box is used for testing and inspecting various components, parts, and finished products for waterproofing, anti fog, and moisture resistance. It can provide realistic simulation of various environments such as water and spray tests that electronic products and their components may be subjected to during transportation and use, in order to test the waterproof performance of various products.

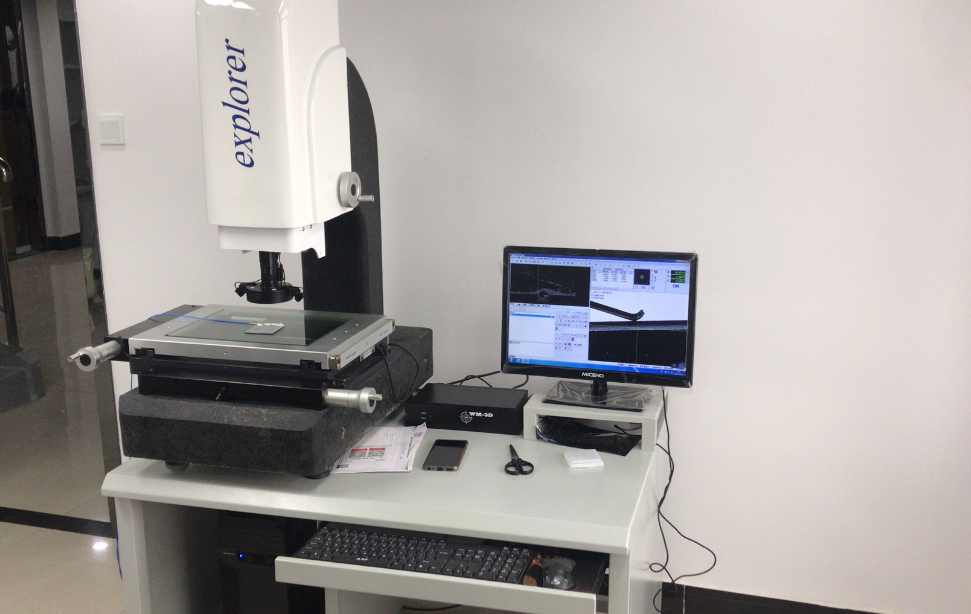

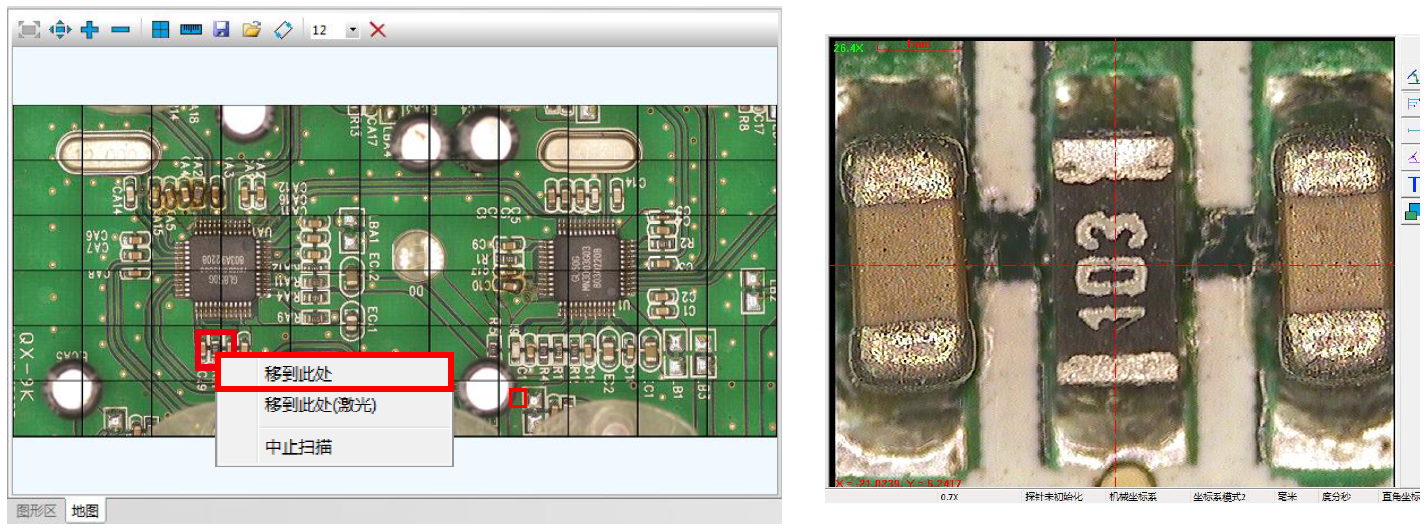

Anime image tester

Anime image measuring instrument realizes artificial intelligence by combining its auto focusing and fuzzy operation of area search, target locking, edge extraction, and point matching, and can automatically correct the deviation caused by workpiece difference and displacement difference to achieve accurate point selection, with high-precision repeatability. Improve the efficiency of batch testing of workpieces to meet the needs of industrial sampling and large-scale testing.